An electric turbocharger is a revolutionary concept. Adding an engine to the turbine shaft simplifies the complexity of traditional turbocharging while also unlocking numerous potential opportunities.

Unlike cars powered by exhaust gases or a crankshaft, an electric turbo has the unique advantage of being assisted by an electrically driven motor connected to the battery. Turbocharging with exhaust gas and electric power to spin the turbines is a must-have innovation in modern engine design. Put simply, the advantages of having an electric turbo are impossible for any car enthusiast to ignore!

How Electric Turbochargers Work

A turbocharger enhanced by electric power can combine a classic exhaust-powered turbine and an electric motor to reduce lag time. This is distinguishable from an electric supercharger, which solely operates on the force of its motorized compressor.

Combines Turbine and Suopercharger

An electric turbocharger is an optimal combination of turbine and supercharger characteristics. Unlike traditional turbines, electric turbos use a motor-powered compressor to force air into an engine’s cylinders. So, you can enjoy this technology’s efficiency in tandem with its immediate power output – truly the best of both worlds!

Faster Acceleration

The engine activates the turbocharger when the accelerator is engaged. At this point, it instantly delivers cold air into the motor. This enables faster acceleration with no delay in response time. Also, when not needed for speed, both motor and compressor will shut down automatically as a power-saving measure – although, due to wheel inertia and exhaust gases combined, it might still spin briefly afterward.

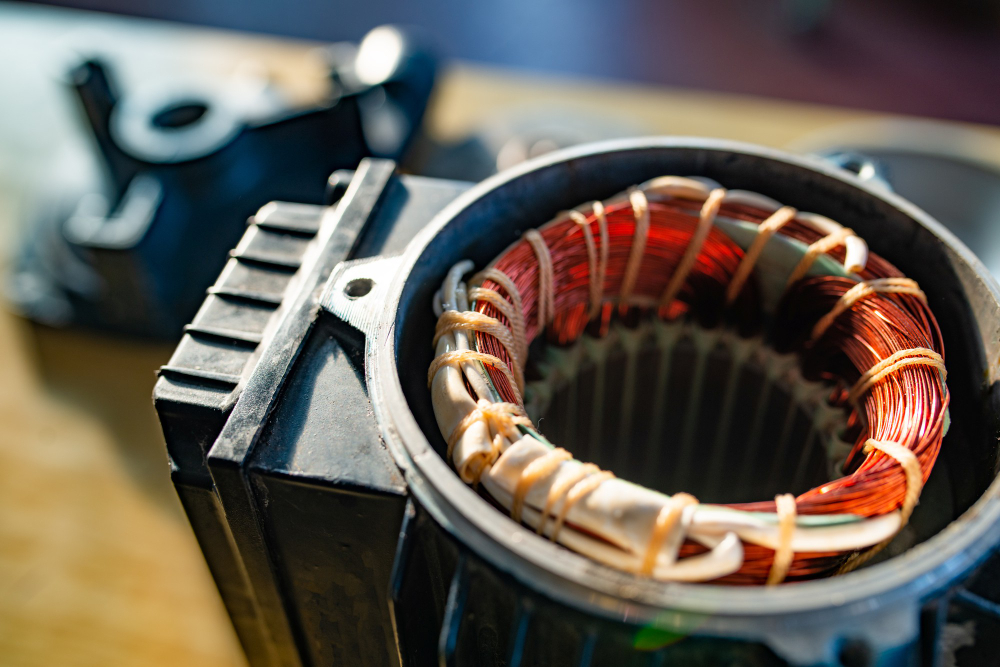

Components of an Electric Turbocharger

The electric turbocharger contains an exhaust gas turbine wheel and a compressor wheel that together magnifies the intake air pressure of any internal combustion engine. Another vital component is the battery. The battery is a power source for the turbocharger’s electric motor, enabling quick acceleration when necessary.

Battery

BorgWarner’s initial e-turbo system operates at 17 kW of peak power, equivalent to approximately 22.8 horsepower (17,000 W). Furthermore, their 400/800-volt e-turbo can achieve up to 34 kW (45.6 hp) during maximum performance. This is significantly higher than the energy supplied by a conventional 12-volt battery.

Types of Electric Turbochargers

The electric turbo industry currently consists of two distinct models: the e-booster (used by Volkswagen Group and Mercedez-Benz) and Garrett Motion’s one-unit e-turbo. Unlike a traditional exhaust-driven turbo, an e-booster is powered solely by motor power – providing instant torque on initial acceleration. When more pressure builds up in the system, it automatically shuts off while relying entirely on its twinned turbine side to carry out any required load work.

Electrically-Assisted Turbocharger

Another type of electric turbocharger is the electrically-assisted turbocharger. The design and powertrain are similar to the e-turbo, except for adding an exhaust wastegate. This controllable valve works closely with the turbocharger’s motor, releasing excess pressure when needed.

Electric Superchargers

Electric superchargers have recently been discussed as a potential vehicle modification. Two varieties of these e-superchargers work differently: the first is more like an air circulation fan than anything else. It’s connected to the inlet manifold and helps draw air into intake valves before forcing it into cylinders for combustion.

The second type of electric supercharger works by taking a donor turbocharger and attaching an electric motor to it, otherwise known as an E-supercharger. Electrical power is then converted into torque so that the impeller within the turbo will spin faster by how much current passes through it. Strategically designed fins inside the turbo carefully compress incoming air to a level that pressurizes air supply for enhanced cylinder performance – resulting in genuine increases in power!

Advantages and Disadvantages of Electric Turbochargers

Like other turbochargers, an electric turbocharger also has certain advantages and disadvantages.

Advantages of an Electric Turbocharger

Electric turbochargers eliminate the problem of turbo lag and insufficient exhaust gases with a direct connection between an electric motor and compressor wheel–it will keep the compressor spinning with electricity when you need it most. You can recover wasted energy from your vehicle’s exhaust turbine, just like those in Formula 1 cars! Moreover, you’ll benefit from an impressively wide RPM range allowing consistent torque. And since the electric turbocharger uses battery power, emissions remain low, and fuel efficiency is much higher.

Disadvantages of an Electric Turbocharger

The cost and complexity of an electric motor are one of its main disadvantages. It is crucial to keep the electric motor and controllers cool to avoid issues with their reliability. The extra weight and packaging associated with the addition of a battery to power the turbo can also be taxing. However, Variable Geometry Turbos (VGTs) or twin-scroll options offer comparable advantages at less cost than their counterparts.

Applications of Electric Turbochargers

Even with some restrictions on electric turbochargers, there are two useful applications for the technology in the aftermarket.

Supplement Existing Turbochargers

One is to use it like automotive factory professionals do – supplement a turbocharger to lessen lag time. The only difference is that this method allows you to fit a bigger turbine size than usual!

Alternative to Full Turbo Systems

The second application uses it as an alternative to a full turbo system. For instance, the Torqamp electric turbo offers higher power and torque return on investment than traditional naturally-aspirated (NA) modifications. Even though it may not give you as much punch as a “real” turbo, bear in mind that if your aspiration is a significant boost from an NA engine, then expect to upgrade various components such as internals and fuel systems plus ECU too.

Electric turbochargers are an exciting new technology that can help to reduce lag time and increase power output. While there may be some drawbacks, such as the cost and complexity of adding a battery or controlling the electric motor, this is an incredibly useful tool for any car enthusiast looking to get more out of their engine. They also offer numerous potential applications in factory cars and aftermarket modifications. Electric turbos increase torque throughout your entire RPM range while reducing emissions – what’s not to love? With further development of these technologies, the industry will likely see even more advancements in performance enhancements from electric turbos in the future!