Cargo loaded onto container trucks have to be secured on all sides to ensure shifting does not occur during transit. The spaces between cargo and the container walls also have to be tightly filled and secured to reduce movement. It’s important to consider that the walls of some vans flex slightly. This means even if the truck is loaded right to the walls, the cargo can still end up shifting and not staying in place. It can be necessary that poles be installed to eliminate risk of shifting.

Transporters will find it relatively simple to load and unload pallets and cargo from their trucks with the use of a trailer skate. But it’s still crucial for heavy cargo to be stored in a way that maximises use of space and eliminates the risk of damage to the product. When they’re well-secured, safety and efficiency will improve significantly.

Tie-Down Ratings

The straps and chains of cargo should be about as heavy as at least half of the load’s total weight. There are more load securing weights for loading and transporting dense cargo.

The load limits of a truck have to be clearly visible and easy to read. Ideally, they are printed or stamped onto the straps of the cargo. The limit set normally depends on the size and type of cargo to be transported.

Normally, the manufacturer’s mark is present in every foot of a chain. But the older and rustier chains may have marks that are more difficult to locate and distinguish. For these types of chains, it can be more difficult for drivers and shippers to ensure its proper load-bearing capacity.

Hazardous Materials

All hazardous substances have to be stored accordingly. They’ll need to be tightly secured so contaminants do not risk spilling over and getting out of containers.

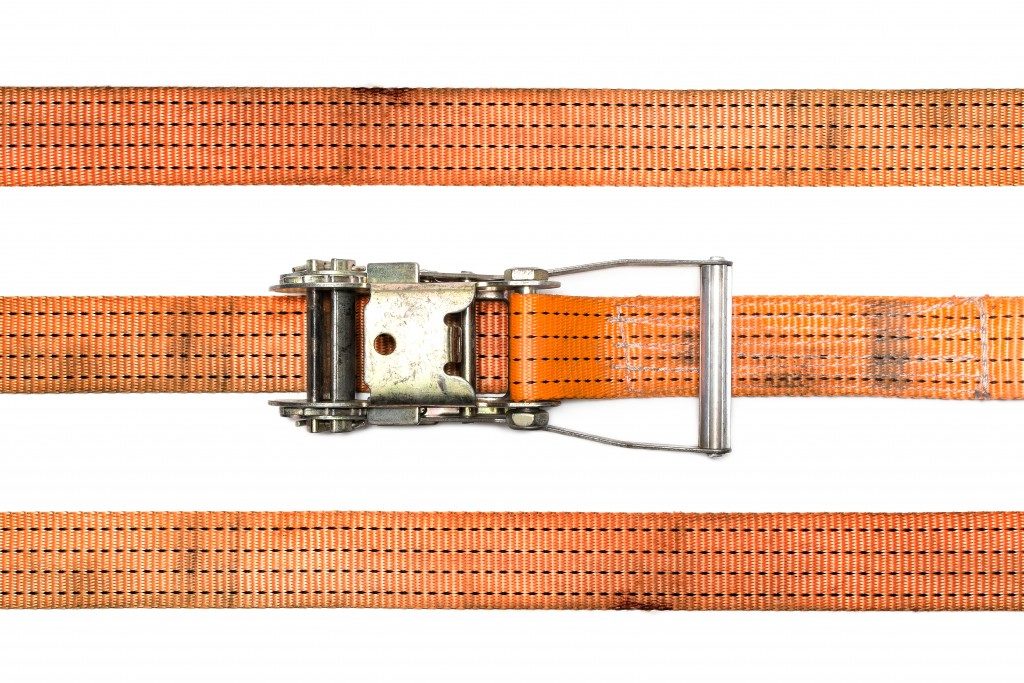

Strap Placement

The weight and friction of cargo placement on a deck can help keep loads from moving around in a trailer. Stacking cargo close to each other can also allow for tighter placement so objects don’t shift.

Denser items like metal coils and rolled paper have stricter requirements for truck securement. These objects can be protected from movement through locking, blocking, latching, or the placement of void fillers and friction mats.

Blocking – Blocking methods include use of the front wall, wedges, and dunnage. They can prevent or reduce cargo from shifting forward and backward in a truck. Dunnage, in particular, fills cargo voids with scrap wood in order to eliminate movement and shifting with vehicle motions.

Lashing – Some lashing items include ropes, cables, chains, nets, and strapping. They help anchor cargo against its position in a container. Applications include top-over, loop, and direct lashings.

Locking – Cargo can also be secured with a mechanical locking system that ensures it remains tied to the load bearer. Containers may have twist locks in place for keeping cargo where it is.

Strapping – This method involves the design of a transportable unit. It can include steel, nylon, paper, and polyester. The strap used also depends on the requirements of the cargo, as whether they have the elasticity, strength, and ability to withstand different environmental conditions.